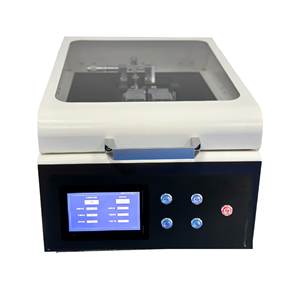

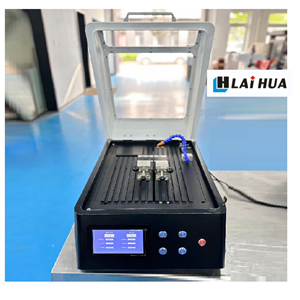

PQG-200 Flat Cutting Machine

Excellent visibility and cutting ability, spacious working space, use of servo motors, high efficiency, simple and stable operation.

1.Product introduction and scope of application

Excellent visibility and cutting ability, spacious working space, use of servo

motors, high efficiency, simple and stable operation.

Suitable for metal, electronic components, ceramic materials, crystals,

cemented carbide, rock samples, mineral samples, concrete, organic materials,

biological materials (teeth, bone) and other materials for precision deformation

cutting. The equipment is equipped with a variety of fixtures, can cut irregular

shape of the workpiece, is the ideal precision cutting equipment for enterprises

and scientific research institutions.2.Product feature

1 Precise program control, high positioning

accuracy.

2 7 inch touch screen, beautiful and elegant

can be preset feed speed.

3 Easy to operate and control, automatic

cutting can reduce operator fatigue and

ensure the consistency of sample

production.

4 Real-time monitoring of the entire cutting

process, alarm tips.

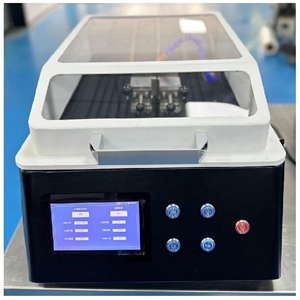

5 Large bright cutting room with safety

switch.

6 Equipped with cooling system and built-in

coolant tank to avoid overheating and

burning samples during cutting.

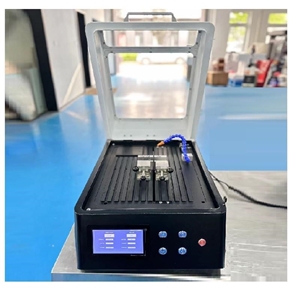

The overall design of the fuselage is exquisite, and the built-in independent

circulation filter cooling water tank is equipped with 80% water and 20% cutting

fluid to mix and lubricate the cutting pieces and samples, effectively preventing

the sample surface from burning and preventing the guide rail and ball screw

from rusting. The machine is equipped with open-cover shutdown safety

protection function, the working area adopts a fully enclosed structure, and has

a transparent protective cover for observation during cutting. The working

platform can be configured with different clamps, and the clamping device can

be freely disassembled and cleaned. The machine body is small but powerful,

can be used in PCB board, Φ30mm or less metal materials, electronic parts,

inserts and other metallographic sample cutting, while the appearance is

beautiful and fashionable, man-machine interface operation is convenient,

cost-effective, is the ideal choice for small workpiece cutting.3.Technical Parameters

Cutting capacity:Φ40mm

Cutting mode: intermittent cutting, continuous cutting

Diamond cutting blade:Φ200×1.0×12.7mm(Can be customized)

Cutting distance:200mm

Speed of mainshaft:50-2800rpm(Can be customized)

Dispaly:7 inch touch screen operation

Cutting speed:0.01-1mm/s

Movement speed:10mm/s(Speed adjustable)

Power:1000W

Power Supply:220V 50HZ

Dimensions:72*48*40cm

Packing Size:86*60*56cm

Weight:90kg

4.Standard Configuration

Water tank pump:1PC(Built in)

Spanner:3PCS

Fastening fittings:4PCS

Cutting Blade:1PC

Quick fixture:1SET

Water pipe:1SET

Power cable:1PC