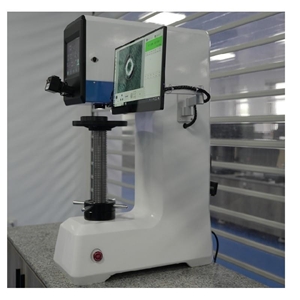

HBST-3000 Digital screen brinell hardness tester with computer

Automatically read value,Automatic measuring indentation brinell hardness tester

Machine Features and Function:

* Integrated product of precise mechanical structure;

* Closed-loop control technology

* Automatic loading, dwell and unloading; electric reversing switch;

* The indentation can be directly measured on the instrument through the micrometer eyepiece;

* Key in the measured indentation diameter, hardness value will be displayed on the touch screen;

* Hardness conversion between different hardness scales;

* Automatic test process, no human operating error;

* Large touch screen of testing process, easy operation;

* Precision conforms to GB/T 231.2, ISO 6506-2 and ASTM E10

Application:

It's suitable to determine the Brinell hardness of unquenched steel, cast iron, non-ferrous metals and soft bearing alloys, etc.

Technical Parameter:

Measuring range: 8-650HBW

Test force: 612.9,980.7,1226,1839, 2452, 4903,7355, 9807, 14710, 29420N(62.5, 100, 125, 187.5, 250, 500, 750, 1000, 1500, 3000kgf)

Max. height of test piece: 280mm

Depth of throat: 170m

Hardness Reading: touch screen

Microscope: 20X digital micrometer eyepiece

Min Value of drum wheel: 1.25μm

Diameter of tungsten carbide ball: 2.5, 5, 10mm

Dwelling time of test force:0~60S

Data output: Printer

Power supply:AC110V/220V 60/50HZ

Machine Dimensions: 581*269*912mm

Net Weight Approx. 130kg, Gross weight: 165kgs

Standard Accessories:

Main unit 1

Brinell standardized block 2

Φ110mm Large flat anvil 1

Power cable 1

Φ60mm Small flat anvil 1

Spanner 1

Φ60mm V-notch anvil 1

Computer, CCD adapter and Software 1

Tungsten carbide ball penetrator:Φ2.5, Φ5, Φ10mm, 1 pc. each

User manual &Certificate : 1

Anti-dust cover 1

Brinell Hardness Indentation Automatic Measurement System

(Can be mounted to hardness tester or work as separate computer)

Main Function:

1. Automatic measurement: Automatically capture the indentation and measure the diameter and calculate the corresponding value of Brinell hardness;

2.

2. Manual measurement: Manually measure the indentation, the system calculates the corresponding value of Brinell hardness

3. Hardness conversion: The system can convert the measured Brinell hardness value HB to other hardness value such as HV, HR etc;

4. Data statistics: The system can automatically calculate the average value, variance and other statistical value of the hardness;

5. Standard exceeding alarm: Automatic mark the abnormal value, when the hardness exceeds the specified value, it automatically alarms;

6. Test report: Automatically generate the report of WORD format, the report templates can be modified by the user.

7. Data storage: Measurement data including the indentation image can be stored into file.

8. Other function: include all functions of image processing and measurement system, such as image capture, calibration, image processing, geometric measurement, annotation, photo album

management and fixed times print etc.

Features:

1. Easy to use: Click on the interface button or press the camera button or press the run button to automatically complete all the work; if need manual measurement or modify the results, just drag the mouse;

2. Strong noise resistance: The advanced and reliable image recognition technology can handle the indentation recognition on the surface of the complex sample, two kinds of automatic measurement mode to deal with the extreme situation;