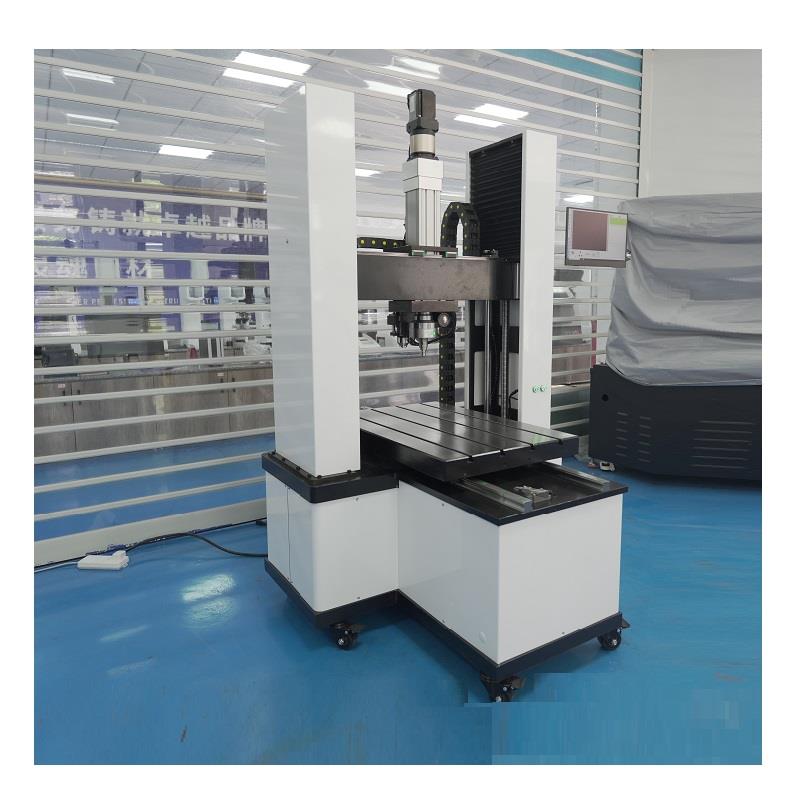

Cellload/Closed loop Brinell Hardness Tester with Measuring System

Large gantry Brinell hardness tester,Electronic Brinell hardness tester/Durometer/Sclermoeter

HBM-3000E Automatic Brinell hardness tester is mainly used for brinell hardness testing of ferrous, non-ferrous metals, bearing alloys,Hard cast steel, aluminum alloy, copper alloy, malleable castings, mild steel, tempered steel, annealed steel etc.. Brinell hardness test is a test method with the largest indentation among all hardness tests. Affected by the micro-segregation and uneven composition of the sample structure, it is a hardness test method with high precision. Measuring range : 5—650HBW.

HBM-3000E Automatic Brinell hardness tester is mainly used for brinell hardness testing of ferrous, non-ferrous metals, bearing alloys,Hard cast steel, aluminum alloy, copper alloy, malleable castings, mild steel, tempered steel, annealed steel etc.. Brinell hardness test is a test method with the largest indentation among all hardness tests. Affected by the micro-segregation and uneven composition of the sample structure, it is a hardness test method with high precision. Measuring range : 5—650HBW.

This machine using frame structure, strong rigidity, small deformation, high stability: suitable for testing large parts. The product is composed of frame, lifting beam, movable workbench, image measuring device, special numerical control system and other parts.

Lifting structure: 4 light rods and 2 ball screw beams form the lifting mechanism structure, which can accurately drive the lifting beam to rise and fall, and its main function is to adjust the test space.

The core spindle components and load sensors are installed on the beam. During the test, the test force is sent to the control system in time through the sensor. Equipped with a large movable worktable, driven by a servo motor, driven by a ball screw to run along a linear guide rail, so that the workpiece to be tested enters and exits the test position. The adjustment of all test parameters and the control of test functions can be completed on the computer.

Numerical control system: It is composed of PLC, servo motor, driver, load sensor, signal converter and other components. During the test, the load signal is sent by the load sensor and transmitted to the system control board. The precise action of the servo motor is controlled by the system control board, which realizes the closed-loop control of the test force and ensures that the test force is strictly controlled within the allowable range.

Instrument Features:

* This instrument has 10 levels of test force and 13 kinds of Brinell hardness test scales, which are suitable for testing various metal materials;The hardness scale can be changed by one value;

* Equipped with 3 ball indenters, which cooperate with the image processing system to realize automatic measurement;

* The loading part adopts standard industrial electric cylinder, which has high working efficiency and very low failure rate;

*The lifting adopts servo motor, precise structure, stable operation, fast speed and low noise;

*The hardness tester and microcomputer are integrated, equipped with Win10 system, and have all the functions of a computer;

* Equipped with a wireless remote control, it is very convenient to use.

*With data storage, automatic calculation of maximum, minimum, and average values, test results can be selectively deleted.

Technical Specifications:

|

Model |

HBM-3000E |

|

Test force |

612.9N(62.5kg),980.7N(100kg),1226N(125kg),1839N(187.5kg),2452N(250kg),4903N(500kg),7355N(750kg),9807N(1000kg), 14710N(1500kg), 29420N(3000kg) |

|

Indenter type |

Hard alloy ball diameter:φ2.5mm,φ5mm,φ10mm |

|

Loading Method |

Automatic (fully automatic loading, dwell, unloading ) |

|

Operation mode |

A Automatic press, test, one key complete |

|

Hardness reading |

Computer digital screen to obtain hardness value |

|

Dwell time |

1-99s |

|

Max height of test piece |

500mm |

|

Distance between two columns |

600mm |

|

Language |

English & Chinese |

|

Effective Field of View |

6mm |

|

Hardness Resolution |

0.1HBW |

|

Min Measuring Unit |

4.6μm |

|

Camera Resolution |

500W pixel |

|

Power |

380V,50HZ/480V,60HZ |

|

Machine Dimension |

1200*900*1800mm |

|

Net Weight |

1000KGS |

Automatic measurement system function and configuration:

1. Industrial camera: 500W pixel COMS special camera (Sony chip) is installed on the beam

2. Computer: Standard all-in-one computer with touch function (installed on the right side of the fuselage)

3. Instrument control: the computer can directly control the host of the instrument (including feedback on the working process of the instrument)

4. Measurement method: automatic measurement, circle measurement, three-point measurement, etc.

5. Hardness conversion: full scale

6. Database: Massive database, all data is automatically saved, including data and pictures.

7. Data query: You can query by tester, test time, product name, etc. Including data, images, etc.

8. Data report: save directly in WORD EXCEL or output with an external printer, which is convenient for users to read and study in the future;

9. Data port: With USB interface and network port, it can be connected to the network and other devices, so that users have more optional functions